Gain a better ROI by Rental or Investment ?

Digitize your production and fabrication

Reenforce automatic data collects. Eliminate paper format in your factory floor. Eradicate double and triple ERP input . Digitize your production in a delay of few weeks without heavy investment.

Your Challenges

- Take action as soon as possible on gaps to avoid production loss or rejection

- Prove fabrication quality in a transparent way

- Identify delta in connection with bill specifications

- Know rapidly impacts in case of production contingencies

- Control traceability during assembly/disassembly

- Guarantee real time traceability, no matter which factory floor contingencies

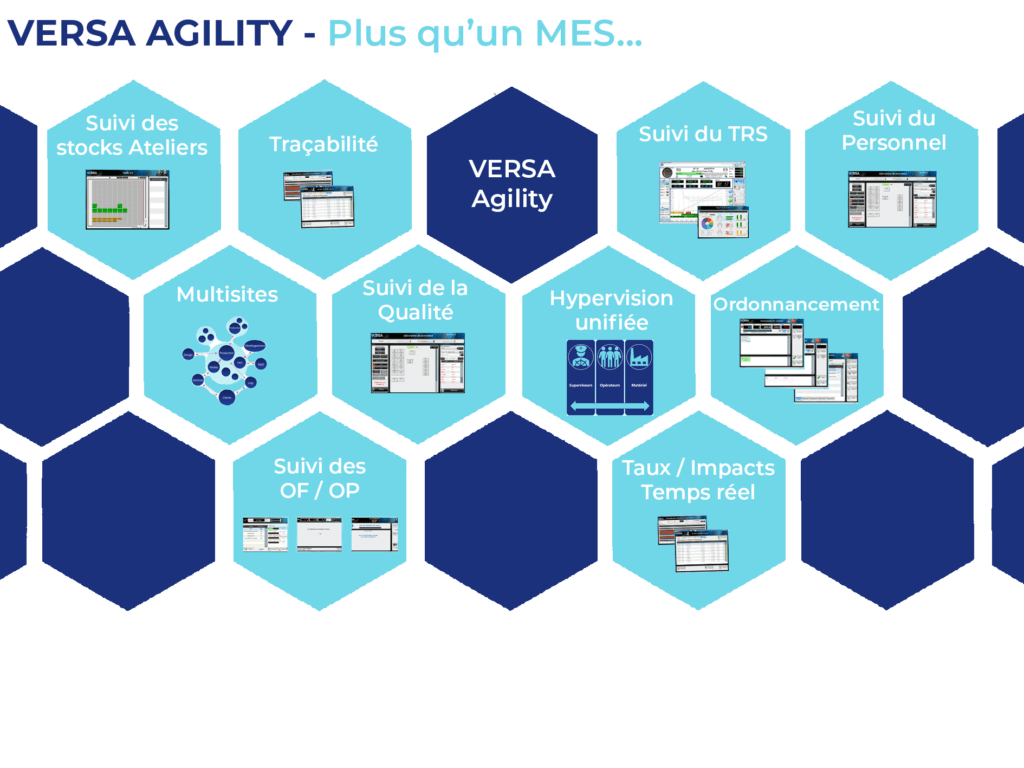

An adapted modular offer

- A generic foundation resulting from customer experiences and our vision of evolution 4.0

- A process of continuous functional improvement

- Investment agility based on priorities

- Flexible specific developments

- A link with the roadmap of operational intelligence and excellence workstations for real-time monitoring of quality, traceability, and synchronization with automation and robots.

Adapted solutions

Revamping or online adaptation :

VERSA proposes to study and carry out all the necessary operations for the replacement of automation of obsolete technology, or of efficiency becoming insufficient.

We have a rare experience in this type of operation thanks to different interventions, Revamping is therefore carried out in very short time in order not to disrupt production.

On-line supervision and piloting or control command system :

Versa designs and implements systems for manufacturing processes whether in continuous mode or in Batch mode.

The systems play a key role in the performance of production units by guaranteeing safety, operating time and control of associated costs.

The line VERSA Logistic Suite

From command picking to the Supply Chain as a whole